Today's newsletter includes new sections on preharvest fruit quality. Many of you are using DA meters for the first time so we offer tips on what you need to know and how to use and interpret the tool. Next is a refresher on the ripening hormone ethylene to set the stage for the products ReTain and Harvista that influence ethylene. We review highlights on ReTain and Harvista from the discussion at last week's Perennia tailgate meeting. We also share information on diagnosing lenticel injury versus bitter pit, and that Apogee is not expected to influence bitter pit incidence. Finally, remember the importance of preharvest fungicide because it is your only protection in storage.

Table of Contents:

- 2023 Degree Day Accumulations

- Precipitation

- Reminders about Fungicide Preharvest Intervals (PHI)

- Preharvest Management of Apple Storage Rots and Fungi

- Fire Blight Management

- Apple maggot

- Calcium Nutrition

- Site Preparation

- Using a Delta Absorbance (DA) Meter

- Delaying or Synchronizing Maturity with ReTain and Harvista

- Estimating Bin Requirements

- Reducing Bruising

- Considering Watercore

- Avoiding Internal Browning

- What's that? Lenticel Injury?

- Ever Wondered about Apogee and Bitter Pit Incidence?

- Consequences of Harvesting too Early

Fruit colouring has improved with recent cool nights that were followed by warm, sunny days. Colouring can continue to improve when nighttime temperatures are below 15°C (or 21°C in the case of McIntosh) followed by daytime temperatures around 20-25°C.

Figure 1: Heating degree day accumulations for plant (above 5°C) and insect (above 10°C) development from March 1 to Sept 1 for the past 17 seasons. Provided by Jeff Franklin (AAFC).

- Approximately 3% less plant development heat units compared to the 5-year average, and 2% less compared with the 10-year average.

- Approximately 7% less plant development heat units compared to 2022, and 7% less compared with 2021.

- Approximately 5% less insect development heat units compared to the 5-year average, and 3% less compared to the 10-year average.

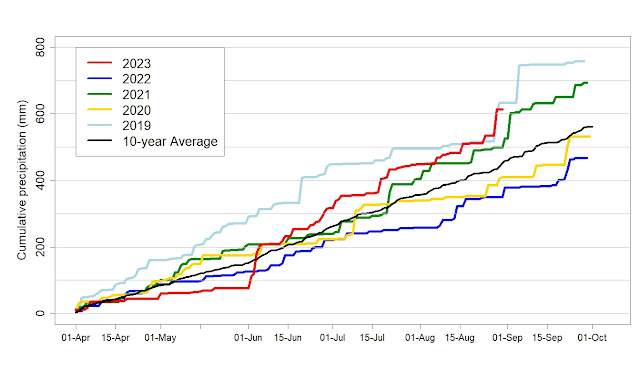

Precipitation

The precipitation total for the growing season is now well above the 10-year average. The current year is tracking similar to the total precipitation received in the wet years of 2019 and 2021 when plenty of rainfall was recorded during the preharvest and harvest period. During recently wet years, the storage losses were relatively high but seemed better off when fruit had received a fungicide near to harvest (as close as PHI allows).

Figure 2: Precipitation recorded in Kentville for the 2023 season (red line) compared with the 10-year average (black line). Provided by Jeff Franklin (AAFC).

Late Season Diseases

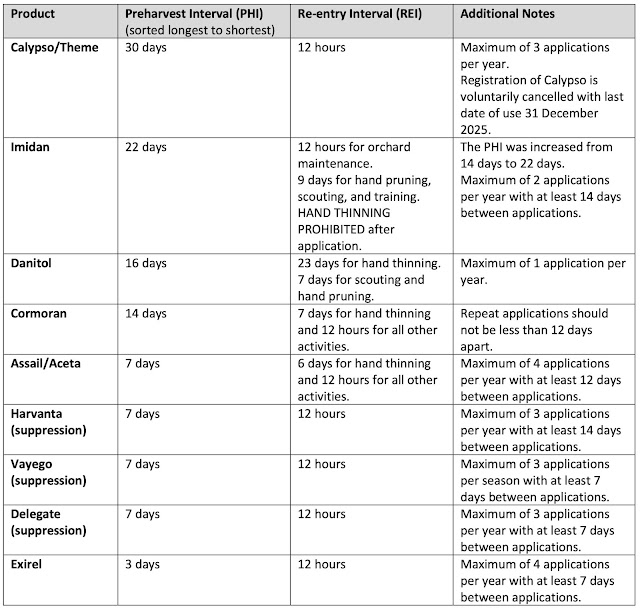

Reminders about Fungicide Preharvest Intervals (PHI)

Table 1: Fungicide products for control of summer diseases listed from longest preharvest interval to shortest preharvest interval. Includes notes about diseases controlled and re-entry intervals (REIs). (Updated on Sept 26 to include Cevya.)

Preharvest Management of Apple Storage Rots and Fungi

A well-timed preharvest chemical control can go a long way to prevent storage rots. Fungal spores that land on unprotected fruit can germinate and symptoms show up as infections in storage. Preharvest fungicide is your only protection in storage.Recommendations:

- Don't put away the sprayer too early! Late varieties benefit from a preharvest spray too. Please note that more rot has been reported in storage in 2021 and 2022 than in prior years and may be related to changes in the Captan use pattern. Growers who stopped their fungicide program early saw early symptoms of diseases in storage.

- The group 7 & 11 products Pristine and Merivon can be applied up to 5 days before harvest. They are labelled for the control of scab, black rot, flyspeck, and sooty blotch. The short PHI and good activity are especially helpful for protecting apples being placed in long-term storage.

- Monitor precipitation during harvest, especially for late-season varieties. Cumulative rainfall of 25-50 mm washes off fungicide protection. The risk of fungicides being washed off is minimized if applied as close to harvest as possible.

- Of course, avoid bruising or wounding to prevent infections of blue and gray moulds. Take the time to educate staff on the proper way to handle fruit.

Fire Blight Management

Fire blight disease is very prevalent this year. Whether it is because late bloom sprays were not applied, there were carryover infections from last year, it was too wet for timely management, hail damage went unnoticed, or the risk was underestimated.

Recommendations:

- Summer pruning other than for the purposes of removing fire blight strikes should be avoided during an outbreak of the disease to prevent further spread.

- Monitor nursery trees and young trees to quickly remove trees with infections. Deer are spreading infections where they graze on young tissue.

- Do not break off branches with fire blight infections as you navigate the orchard. Research shows that the bacteria becomes systemic in the tree because branches are not adequately removed. There are then a high number of new infections and significantly more canker tissue and cankers on structural wood.

- Prune out fire blight infections on young trees in the current year as soon as you notice infections - don't wait for winter. Trees 8 years old and younger are at the greatest risk of rootstock blight.

- Remove fire blight strikes at least 2-4 ft below active infections to remove the leading edge of the bacteria. The younger the tree, the deeper the cut. Being aggressive at the first sign of symptoms will help prevent the re-occurrence of symptoms and the need for continuous cutting back. Repeat tree inspections at least weekly.

- Cut out infections when a period of 2 dry days are in the forecast. Leave prunings in orchard laneways to let dry thoroughly for several weeks. If cutting a whole tree consider letting it dry while attached to the trellis. Don’t make piles that will prevent the wood from drying.

- Do not cut root suckers during an outbreak because the wounds are susceptible to infection. Instead, remove suckers during the dormant season.

- Potato leafhoppers can transmit fire blight. Their presence in young plantings and nurseries is concerning, especially in areas of active fire blight infections.

Insects

Insect management programs should be based on grower monitoring and/or scouting reports.

- Apple Maggot

- Table 2 provides a list of insecticide products for apple maggot control with their respective preharvest and re-entry intervals.

- Even if your orchard has already been inspected for apple maggot, do not stop spraying prematurely as flies will continue laying into September.

- Clean maggot traps 7 to 10 days after treating a block for maggot and monitor for new trap captures. Re-treat if new maggot flies are caught. Flies emerge over a period of time so for satisfactory maggot control, monitor the presence of apple maggot flies to inform treatment programs. Remember, a single female can lay hundreds of eggs.

- Significant rainfall will wash off insecticide residues that are needed to ward off apple maggot flies. Re-treatment is required after 10-14 days or cumulative rainfall of 12.5-25 mm (0.5-1 inch). Danitol and products registered for suppression are expected to have a relatively shorter field residual life of 7-10 days.

- Apple maggot flies are weak flyers so a border/perimeter spray of Imidan near known hotspots may be an approach to help kill adult flies from the source.

- Apple maggots pupate in the soil and may not emerge until up to four years later. Therefore, several years of diligent management are required to reduce the resident insect population.

- Remember, apple maggot is a neighbourhood problem and last year had higher than normal fruit damage.

Table 2: Insecticide products for control of apple maggot listed from longest preharvest interval to shortest preharvest interval. Includes re-entry intervals (REIs) and additional information.

Horticulture

Calcium Nutrition

- This year the wet weather is encouraging plenty of vegetative growth. The leaves compete with the fruit for calcium so the lush growth may dilute the calcium in fruit. Therefore, calcium applications are highly recommended this year.

- The recommended rate is 4 to 14 pounds of elemental calcium per acre in a season spread over six to eight cover sprays.

- Low rates will not cause leaf burn but will likely lead to only minor control of bitter pit and likely will not enhance storage life of the fruit.

- High rates may lead to some leaf burn, give good control of bitter pit, and may also enhance storage life of the fruit. High rates are recommended for Honeycrisp.

- Calcium applied at two-week intervals is better than occasional, high-rate applications.

- For help calculating the amount of elemental calcium you are applying in each spray, visit Penn State Extension to download a calcium rate calculator. The percentage of elemental calcium will be listed on the label of your product of choice. Check formulated calcium products because they may not contain as much calcium as you expect.

- Ca has very low movement within the tree and needs to be applied directly to the fruit surface to be absorbed. Therefore, thorough coverage is important to cover developing fruit.

- Calcium chloride flake (77% Ca) is the most economical Ca material to use but also the highest risk for foliar burn. Calcium chloride flake is safe when applied at 4.5 kg per 1000 L of spray solution. The risk of leaf or fruit damage from calcium is highest in hot weather. Susceptible varieties can develop lenticel spotting if damaged.

- Calcium chloride flake can be rough on equipment. Use a pressure washer to clean equipment. Consider spraying your spray equipment with superior oil before beginning and the calcium will wash off more easily.

- Calcium chloride is a worthwhile management strategy for bitter pit, even if it has to be applied alone. Waiting for a tank mix partner may mean that ideal application timings are missed.

- Note that nutrient product formulations with calcium may contain boron that would interact poorly with water soluble packaging.

Site Preparation

- Getting ready to plant trees in the spring of 2024? This season is a good time to incorporate limestone, nutrient additions, rip, level the surface, lay out the rows, or plant an overwintering cover crop to hold the soil.

- The Limestone Trucking Assistance Program is accepting applications until September 30, 2023. The application and guidelines are available online here or contact your local Agricultural Office for assistance.

Harvest Fruit Quality

Using a Delta Absorbance (DA) Meter

Many new DA meters are being used in the industry this year so it might be time for a refresher on the topic. What is a delta absorbance (DA) meter, how does it work, and how is it used in the field?

The DA meter is a handheld device used to monitor the chlorophyll content of the apple peel as an indication of fruit maturity. Chlorophyll degrades as the fruit matures so the reading correlates with other changes that happen during the ripening process. The device works by shining LED lights onto the apple skin and records a value from the light-based reading.

What you need to know:

- Varieties have a unique set of DA meter values associated with them that are the boundaries of when to begin and end harvest, based on local research by AAFC. This means that you cannot test a McIntosh or Cortland and expect it to match values set for Honeycrisp.

- DA meter values become smaller as fruit matures. Typically the readings will change by 0.1 units in one week (ex. from 0.6 to 0.5).

- The late Dr. John DeLong who spearheaded local research on the topic recorded a podcast with us in 2019 on 'Sensing Fruit Maturity'.

Using the DA meter:

- Years ago Joan Hebb created a handy Quickstart Guide. Follow the instructions for calibrating and clearing the mean values.

- Leave the fruit on the tree but ensure that leaves are not caught between the LED sensors and the fruit surface.

- Take a reading on the average sides of each apple (imagine an apple has four sides, ignore the sun-exposed and shade-exposed sides and use the remaining two sides).

- Test a minimum of 20 apple samples randomly from each block by measuring 10 apples from one side of the row and 10 apples from the other side (10 apples x 2 fruit sides x 2 row sides = 40 readings).

- Record the average result calculated by the device then clear the mean value to start over in the next block. Keep your records because it will be valuable to compare blocks within a year and between years. Record the block name and successive dates of measurement.

- Honeycrisp with a DA meter reading above 0.59 is too immature to harvest, 0.59-0.36 is optimally mature and best for storage, and below 0.36 is over mature and susceptible to storage disorders so is best sold immediately (DeLong and others, 2014).

- The DA meter boundaries for Ambrosia destined for long term storage are 0.47 to 0.28 (DeLong and others, 2016).

Recommendations:

- Start taking sample readings 2-3 weeks before the predicted harvest date to anticipate the rate of change and the approaching start time. One of the major benefits of the DA meter is using the readings to chart the progression of maturity and to compare blocks so that more mature blocks can be harvested before others.

- The DA meter values for optimum harvest may vary each year so it is still important to regularly do a taste test and starch test. The DA meter helps to increase the frequency of sample testing and the sample size.

- DA meter values may not be representative of fruit maturity on fruit treated with ReTain or Harvista so consider other maturity indicators. The chlorophyll degradation might be affected by ReTain and Harvista and could be misaligned with typical DA meter values.

Figure 3: The DA meter is a handheld device to monitor apple fruit maturity on varieties with known DA meter harvest protocols. A minimum of 20 fruit in each block should be sampled with readings on the sun and shade exposed sides of each fruit.

Delaying or Synchronizing Maturity with ReTain and Harvista

The Ripening Hormone Ethylene

ReTain and Harivsta products delay fruit maturity through their impact on the plant hormone ethylene, so let's take a step back and review how ethylene production occurs in apple fruit.

- Ethylene is a gaseous hormone produced by the apple fruit that accelerates the ripening process.

- When fruit reach a certain stage of development, ethylene production begins to escalate. When the escalation begins the ethylene production is analogous to an unstoppable freight train. The internal ethylene concentration rises, the hormone is recognized within the fruit and then processes are signalled to quicken fruit maturity.

- The capacity for ethylene production varies between apple varieties. Honeycrisp and Gala have less capacity to produce ethylene than McIntosh.

- Research has discovered products that manage ethylene in plants:

- ReTain stops ethylene production. If ethylene production is stopped early in the process then the internal fruit concentration stays low. Application 3 to 4 weeks before harvest is expected to keep the internal ethylene low. In our analogy, using ReTain means that the freight train coasts but does not gain speed until the ReTain wears off.

- Harvista stops ethylene action within the fruit. The ethylene is present but it isn't recognized within the fruit so ethylene does not quicken fruit maturity. The freight train freezes until Harvista wears off.

Summary of Discussion at the Perennia Tailgate Meeting

Thank you to Stirlings Mountainside Farm for hosting us for a discussion on Sept 1!

- There are many remaining questions and there will be more on-farm experimentation this year so we plan to meet again next year to revisit this topic.

- The main concern with ReTain on Honeycrisp appears to be the colour delay and for that reason there is hesitation to apply it more than 2 weeks before harvest.

- Don't apply ReTain if the block already struggles to get good colour development or if it has a heavy crop load and will have trouble gaining colour.

- In general there is comfort using ReTain on Gala at 2 weeks before harvest, especially to prevent greasiness and cracking.

- We discussed interest in the flexibly offered by Harvista. Harvista can be applied up to 3 days before harvest meaning that red colour is allowed to develop first and harvest dates are predictable. Harvista has an increased cost but several growers argue that an extra bin or two can make up the cost.

- There is interest in using a program of ReTain followed by Harvista for even greater harvest delay. There is limited local experience but experience with Gala suggests positive results using 1/2 rate ReTain on Sept 1 and 1 gal/ac Harvista on Sept 26. Gala harvest was extended until Oct 17 using this combination of ReTain and Harvista.

- DA meter readings after Harvista/ReTain might not actually represent maturity. Changes to chlorophyll content caused by these products might not be synchronous with other maturity indicators.

- If you are testing a rate or timing, leave a small untreated area within the block for comparison.

The Preharvest Management Strategy:

- As even more new plantings come into bearing, consider the advantages of harvest management tools to help slow fruit maturity as you manage labour resources.

- Both ReTain and Harvista can help reduce the incidence of watercore and internal browning by delaying maturity.

- Consider testing ReTain or Harvista on a small block and talk to others who have experience using them. Do not give up after one attempt with these products, especially if last year was your first test. Last year was an anomaly with conditions that did not support colour development. Also experiment with different rates, timings, and varieties.

- These products are not expected to prevent the structural stem damage that is associated with windfalls from high winds.

ReTain

Recommendations:

- Note that the amount of ethylene produced differs by apple variety and so the variety’s response to ReTain will also differ. McIntosh is a high ethylene-producing variety and the full rate is often needed 3 weeks before harvest to slow its maturity. Sensitive varieties like Gala, Jonagold and Honeycrisp produce low ethylene and are more sensitive and thus greatly delayed by full rates of ReTain. For Honeycrisp, local success is achieved with the half rate at 14 or 7 days prior to harvest.

- ReTain applied 3-4 weeks before harvest will delay the harvest period up to 7 to 10 days.

- The effectiveness of ReTain is dose-dependent and time-dependent. Later applications and smaller doses have less effect on maturity and colour development.

- For a multi-pick harvest, ReTain applied 7 to 14 days prior to the anticipated start of the 1st harvest can improve the quality and storage potential of 2nd and later picked apples. First picks will not be affected but later picks will be delayed. Note the PHI of 7 days.

- Xiameter surfactant is recommended at a concentration of 0.05 to 0.1% (v/v) in the spray tank. To prevent possible spotting on fruit, use the 0.05% (v/v) concentration.

- ReTain is not a systemic product. Good coverage of both fruit and leaves is important to response.

- On the label, there is a caution stating that the fruit on heat- and water-stressed trees may not respond to the product.

Harvista

Recommendations:

- Harvista can be applied 3 to 21 days before the anticipated harvest and at a higher rate for fruit that are more advanced in maturity and producing plenty of ethylene.

- Harvista will delay the harvest period up to 7 to 14 days.

- Typically the product will reduce the number of harvest picks because it helps to synchronize the maturation rate.

- Lower rates are recommended for biocoloured apple varieties to allow colour development to progress. It can delay red colour development on Gala and Ambrosia so apply after colour has developed at close to 3 days before harvest. It also reduces stem splits on Gala.

- A customized sprayer system is required for Harvista applications.

- A calibration video is available on the AgroFresh YouTube page.

- The Harvista Calibration Tool is available on Google Play and the Apple Store.

Estimating Bin Requirements

Large apples fill bins a lot quicker than small apples. If fruit in a block are a relatively uniform size, then a little math can help you estimate bin requirements. The crop volume is determined by the number of trees, number of fruit, and fruit size.

To approximate the number of bins required:

- Calculate the number of apples per acre (# trees per acre x avg # apples per tree)

- Refer to table 4 for the # of apples per 17 bu bin of a selected average count size

- Bins/acre = # of apples per acre / # apples per bin for selected count size

Table 3: Number of apples of a selected count size to fill a 17 bu bin.

Example 1: 125 count size

- 1000 trees per acre x 60 apples/tree = 60,000 apples/acre

- There are 2125 apples per bin of 125 count size.

- Bins/acre = 60,000 apples per acre/2125 apples per bin = 28.2 bins/acre

Example 2: 113 count size

- 1000 trees per acre x 60 apples/tree = 60,000 apples/acre

- There are 1921 apples per bin of 113 count size.

- Bins/acre = 60,000 apples per acre/1921 apples per bin = 31.2 bins

Reducing Bruising

Recommendations:

- Apples picked after significant rain will bruise more easily than if they’re picked when the soil has a lower moisture capacity. This information might be helpful for varieties especially sensitive to bruising.

- Let fruit warm up before harvesting. Apples picked in the cool weather of early morning bruise more easily than those picked in the day’s warmth. Generally, susceptibility to bruising decreases gradually from 0 to 15°C.

- Take the time to educate staff about the proper way to perform harvest activities that reduce bruising. For example, pick the bottom of the tree first, don’t overfill the picking bag, avoid long harnesses that let the bag bump against knees when walking, explain the difference between varieties etc.

- Re-grade orchard roads prior to harvest to lessen bumps that would jostle fruit being transported in bins.

- Have an inspector sample fruit from various positions in the bin two times each week and leave at room temperature for 24 hours to check for signs of bruise development.

- If bins of fruit will sit in the orchard during overnight freezing temperatures, place the bins where they will be shaded from direct morning sun. Direct sun will warm the fruit too quickly and can lead to deep and lasting bruises.

Considering Watercore

Watercore is a fruit disorder closely associated with over-mature apples along with several other factors. It happens most frequently in years with high sunshine and lack of cloudy, rainy days. Also, highly coloured and large fruit are most prone to the disorder. Fruit with the disorder have an appearance of water-soaked flesh because the spaces between the cells become concentrated with sugars instead of air. Small signs of watercore can disappear in storage and add sweetness to fruit. However, more serious watercore can reduce gas exchange in the fruit and lead to internal breakdown.Recommendations:

- Mature fruit are more likely to develop the disorder because as fruit mature the starches are converted to sugars. The sugar solution builds up in the fruit. Blocks that have a history of watercore should be harvested before other blocks.

- Consider products to delay harvest maturity. Both ReTain and Harvista labels state delayed onset and incidence of watercore.

Avoiding Internal Browning

Internal browning is likely related to carbon dioxide injury. The disorder frequently occurs in overmature and large fruit that have high carbon dioxide concentrations. In particular, fruit harvested late in the harvest window are most susceptible because as fruit mature their ability to diffuse internal carbon dioxide concentrations decreases. The internal carbon dioxide builds up and increases the chance of injury. Consider using products that delay harvest maturity.What's that? Lenticel Injury?

If fruit have symptoms that don't quite resemble bitter pit, it could be because the issue is actually lenticel injury. Lenticels function as pores in the fruit skin to exchange gases from the inner fruit and the outer atmosphere. The cells that make up these pores are susceptible to cracking if they are damaged by environmental factors or chemicals. Too much or too little water can damage cells by causing them to grow or shrink too quickly, and sun and heat stress can also interfere with normal functioning.

Figure 4: The spots caused by lenticel injury versus bitter pit can be difficult to differentiate. Photos A & C by Dr. Paul Hildebrand in 2017.

Ever Wondered about Apogee and Bitter Pit Incidence?

The question of Apogee's influence on bitter pit has come up and there was a study published in 2018 by Lee Kalcsits lab that explored this very question. The work was done in Washington so it may not be directly applicable to our region but what they conclude leads me to be unconcerned about the use of Apogee.The study by Serban and Kalcsits investigated the influence of shoot extension growth on bitter pit incidence. They did so by testing several rates of Apogee that inhibited shoot growth and the opposite treatments of stimulating shoot growth using the plant hormone gibberellic acid. The study was done using Honeycrisp and bitter pit was assessed after 4 months of storage. In the two-year study, none of the treatments significantly affected the amount of calcium in the fruit or the incidence of bitter pit. Good to know!

The researchers suggest that although Apogee controls shoot extension it doesn’t affect the vigour in terms of mineral balance. Apogee reduces shoot length but the number of internodes stays the same.

Consequences of Harvesting too Early

While trying to avoid overmature fruit, avoid the other extreme as well – immature fruit. Picking fruit too early has penalties. Fruit continue to grow as they mature so a 1/4 inch increase in size from 2 3/8 to 2 5/8 can translate into a 35% increase in fruit volume. It takes just as long to pick one large (88 count) apple as it does to pick one small apple (160 count). But it will take half as long to make up a bushel of large apples than small. So picking cost and time required are less for larger fruit. Picking too early can also sacrifice fruit colour and reduce pack out. Immature fruit bruises easily and is subject to scald, shriveling in storage, and poor flavour.Pest Management Guides 2023

All changes new to 2023 are made in red text directly on the guides. The information on all expected changes was summarized in a blog post on March 7.Decision Tables

- Download the 2023 Petal Fall Insecticide Decision Table

- Download the 2023 Prebloom Insecticide Decision Table

- Download the 2023 Fungicide Decision Table

Guides

- Download the 2023 Pome Fruit Management Guide

- Download the 2023 Organic Apple Management Guide

- Download the 2023 Stone Fruit Management Guide

- Download the 2023 Thinners and Growth Regulators Guide

- Download the 2023 Tree Fruit Weed Management Guide

This Orchard Outlook has been published with the input of the Orchard Outlook Committee including this week's contributors: Joan Hebb, Danny Davison, Kari Brown, Jeff Franklin, and Heather Rand.

Perennia Food and Agriculture Corp.

Edited by Michelle Cortens, Tree Fruit Specialist